|

Facility |

||

|

Our Lab · Home · People Projects ·

VTOL MAV |

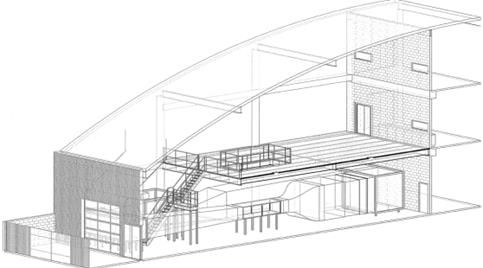

Micro Air Vehicles Laboratory. MAV Laboratory is

located in room N341N in the Department of Aerospace and Mechanical

Engineering at the University of Arizona. The mission of the Laboratory is to

provide researchers with the space, equipment, and tools for the design,

fabrication, and testing of aircraft structures. The laboratory’s space is

3600 sq. ft. The laboratory houses the following research facilities: a wing

loading setup; composite part manufacturing equipment, test stands to

facilitate studies of power plants, navigation, and controls of aerial

vehicles. The experimental work is supported by the professional AME machine

shop (3 full-time staff) equipped with several manual/CNC

routers/mills/lathes and a composite machining laboratory.

University of Arizona Wind Tunnel. A

new closed-return subsonic wind tunnel was recently installed in the

Aerospace and Mechanical Engineering Department with funding from AFOSR and

the University of Arizona. This multi-purpose, optically accessible facility

has a 3ft by 4ft test section and a maximum tunnel speed of ~80 m/s (Remax≈5x106

m-1) with mean flow uniformity better than +/-1%. A key feature of the tunnel

is the 450-horsepower two-stage pneumatically controlled pitch axial fan with

two 250 HP TEAO motors. It allows adjustment of freestream

conditions by fan rev/min or blade pitch, or both. This is particularly useful

for sensitive experiments that necessitate fine tuning of freestream

conditions. Flow conditioning upstream of the 6:1 contraction section

includes a high-aspect-ratio precision hexagonal-cell aluminum honeycomb with

six seamless high-porosity stainless steel screens.

The wind tunnel project also includes state-of-the-art

instrumentation. The majority of equipment is modular and expandable to

support a wide variety of future test needs: · 2D/stereoscopic/tomographic-capable PIV and DIC system (Lavision). · Miniaturized static pressure scanners (128 channels, Scanivalve ZOC33). · 16 channel high bandwidth signal conditioning amplifiers (Ectron Model 563HL) · 9 channel selectable low/high pass filters (Kemo

Benchmaster 21M) · 16 channel simultaneous sampling high-speed data acquisition

system (NI PXIe). · 4 channel constant temperature anemometry (CTA) system (Dantec Streamline Pro). · 5 component external balance. Micro Air Vehicles Wind Tunnel. The MAV wind tunnel facility is located in the room N221N in

the Department of Aerospace and Mechanical Engineering. The tunnel is

equipped with 7.5 HP motor powering the fan. The wind tunnel is a closed-loop

tunnel that is capable of airspeeds up to 20 m/s. The wind tunnel test

section is contained within a small room at ambient pressure to minimize

potential disturbances on the flow. The nozzle outlet is 0.35 m by 0.45 m and

it is 1.24 m away from the diffuser’s inlet. The contraction ratio is 4.5,

and the turbulence level is 0.3%. An industrial frame set is installed in the

test section (outside of the flow) to mount various experimental apparatus

including: a robotic arm R12 by ST Robotics, an aerodynamic balance and a

high-speed video system Phantom 9.1v. Forces and moments are measured by

custom-designed 6-component micro external and sting balances. The tunnel is

suited for the development and testing of small airframes, such as of

Unmanned Air Vehicles.

|

|